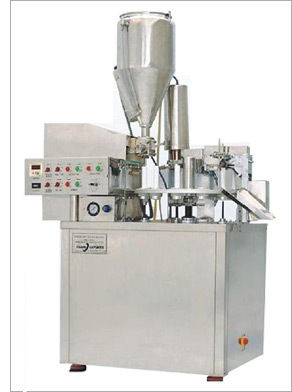

Semi Automatic Tube Filling Machine

Product Details:

Semi Automatic Tube Filling Machine Price And Quantity

- 1 Piece

- 300000.00 - 600000.00 INR/Piece

Semi Automatic Tube Filling Machine Trade Information

- MUMBAI

- Telegraphic Transfer (T/T) Letter of Credit (L/C) Letter of Credit at Sight (Sight L/C)

- 3 Piece Per Month

- 6-7 Week

- WOODEN CASE

- All India

- GMP Compliant

Product Description

Semi-Automatic Tube Filling Machine is intended to fill and seal aluminum/plastic/lami tubes. The machine is reasonable basically for pharmaceutical restorative and sustenance industry. Machine can be utilized for filling of cream treatment, gel glue analgesic and other comparative thick items by methods for a volumetric dosing framework. The machine is accessible with two setups: 1) for aluminum tubes 2) for lami plastic tubes.

- Operation System: Single Head, Rotary Index Table

- Tube Diameter Minimum 12 mm to maximum 50 mm

- Tube Length Minimum 50 mm to maximum 220 mm

- Tube Loading Manual

- Tube Orientation: Manual

- Product Handle Gel paste balm Cream, ointment and other kindred viscous products.

- Tail Cutting: By suck-back technique (to avoid dripping after filling process)

Output up to 1800 tubes in every hour for alu tubes / 2400 tubes per hour for lami and plastic tubes

Product Hopper S.S. 304 50 liters capacity. Hot water circulation pump with water jacket of electrical heating is optional

Product Agitator Slow speed agitator is rendered for stirring of product in hopper as an alternative.

Filling Nozzle Fixed nozzle, with tube lifting at filling station to lift up the tube so that spout gets injected inside tube while filling.

Dozing Range

- a) 3 to 30 ml

- b) 30 to 100 ml

- c) 100 to 250 ml

Tube Discharge: Automatic, through a discharge shaft for collection

Tube Sealing: By double fold as well as and crimping tool for aluminium conduits

By hot air tool for plastic as well as lami tubes

Batch Code Adornment: In crimping jaws for alu tubes

In sealing jaws for plastic / lami tubes

ATF is made to fill as well as seal aluminium / plastic / lami tubes. The machine is appropriate primarily for cosmetic pharmaceutical and food industry. These machines can be employed for filling of ointment gel paste cream balm and other related viscous products via means of a volumetric dosing system. These machines are accessible in two configurations for aluminum tubes as well as for lami plastic tubes. The operation system of this machine is single head with rotary index table. It comes with output up to 1800 tubes in all hours for alu tubes / 2400 tubes per hour for lami as wellas plastic tubes.

- Product Handled: Paste balm cream ointment gel and other similar viscous products.

- Tube Length: Minimum 50 mm to maximum 220 mm

- Tube Diameter: Minimum 12 mm to maximum 50 mm

- Tube Orientation: Manual

- Tube Loading: Manual

Product Hopper S.S. 304 50 liters capacity. Water jackets are rendered with electrical heating as well as hot water circulation pump optional

Product Agitator Slow speed agitator for the process of stirring in hopper as the optimal option

Filling Nozzle Fixed nozzle offered with tube lifting at filling station to upheave the tube so that nozzle gets introduced inside pipe while filling. Diving nozzle optional FILL system combined.

Tail Cutting By suck-back technique (to preclude dripping after filling process)

Dozing Range:

- a) 3 to 30 ml

- b) 30 to 100 ml

- c) 100 to 250 ml

Tube Sealing By double fold as well as crimping tool for aluminium tubes

By hot air tool for lami and plastic tubes

Batch Code Embossing: In crimping jaws for alu pipes

In sealing jaws for plastic as well as lami tubes

Tube Ejection: Automatic via an ejection chute for collection

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+