Showroom

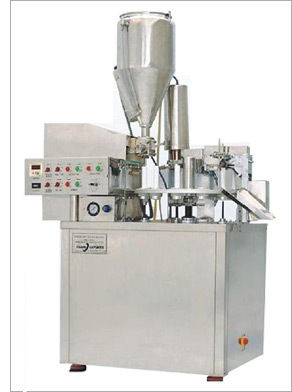

PLC operated Pharmaceutical Filling Machine is acknowledged for its error free operation. Vertical sealers of this machine are meant for avoiding shrinkage during sealing. High speed operation, long working life and low operating cost are its main attributes.

Offered range of automatic Capsule Filling Machine boasts of having PLC based mechanism, AC drive equipped speed controlling function and touch screen based operating mode. User friendly design is one of its main features.

Food grade stainless steel made Blister Packaging Machine is capable of forming, punching and sealing of pharmaceutical blisters at the same time. This equipment is offered in different weight, working capacity and stroke rate based options.

This table-top leak testing machine can be used to inspect leakage in sealed or crimped tubes, sachets, pouches, capped bottles, induction sealed containers, etc. This is an essential machine required in packaging units of many industrial sectors.